Xa usika i-carbon steel, oomatshini bokusika i-laser bavame ukusebenzisa iigesi ezincedisayo ekuncedeni ekusebenzeni.Iigesi ezincedisayo eziqhelekileyo yioksijini, initrogen kunye nomoya.Uthini umahluko phakathi kwezi gesi zintathu xa usika intsimbi yecarbon?

Ukuqonda impembelelo yegesi nganye encedisayo kwinkqubo yokusika, kuyimfuneko ukucacisa umgaqo wendima yeegesi ezincedisayo.Okokuqala kuzo zonke iingenelo zokusebenzisa umoya wokusika zicacile ngokwaneleyo, akukho zindleko ezifunekayo.Xa usebenzisa umoya, kuphela iindleko zombane ze-compressor yomoya kunye nomatshini ngokwawo kufuneka zithathelwe ingqalelo, ukuphelisa iindleko eziphezulu zeegesi ezincedisayo.Ukusebenza kakuhle kokusika kumaphepha amancinci kuthelekiswa nokusika i-nitrogen, okwenza kube yindlela yoqoqosho kunye neyobuchule yokusika.Nangona kunjalo, ukusika umoya kukwanezinto ezingeloncedo ezicacileyo ngokwemigaqo yecandelo elinqamlezileyo.Okokuqala, umphezulu osikiweyo unokuvelisa ii-burrs, ezifuna ukusetyenzwa okwesibini ukucocwa, ukonakalisa umjikelo wemveliso ngokubanzi.Okwesibini, umphezulu osikiweyo unokuba mnyama, ochaphazela umgangatho wemveliso.Ukusetyenzwa kweLaser ngokwayo kuthatha inzuzo yokusebenza kakuhle kunye nokuchaneka komgangatho, kwaye iingxaki zokusika umoya ziye zakhokelela abathengi abaninzi ukuba balahle olu hlobo lokusika.

Okwesibini, ukusetyenziswa kwe-oksijini yokusika, ukusika i-oksijini yindlela eqhelekileyo kunye neyomdabu yokusika.Ukusetyenziswa kwe-oxygen fiber laser cutting machine iinzuzo zayo zibonakaliswa ngokukodwa kwiindleko zegesi, ekuqhutyweni kwe-carbon steel-based sheet sheet, ngaphandle kokutshintshwa rhoqo kweegesi ezincedisayo, ukwandisa ukusebenza kakuhle, ulawulo olufanelekileyo.Nangona kunjalo, into engalunganga kukuba emva kokusikwa kwe-oksijini, kuya kubakho ifilimu ye-oxide phezu kwendawo yokusika, ukuba le mveliso enefilimu ye-oxide ngokuthe ngqo kwi-welding, ixesha liya kuba lide, ifilimu ye-oxide iya kugqabhuka ngokwemvelo. imveliso iya kwenza i-welding yobuxoki, echaphazela umgangatho we-welding.

Xa i-oksijeni isetyenziswe njengegesi encedisayo, ifilimu ye-oxide yenziwe kwindawo yokusika.Umphezulu we-oxide-free cuts ngokubanzi umhlophe kwaye unokudityaniswa ngokuthe ngqo, ipeyintiwe, njl njl.

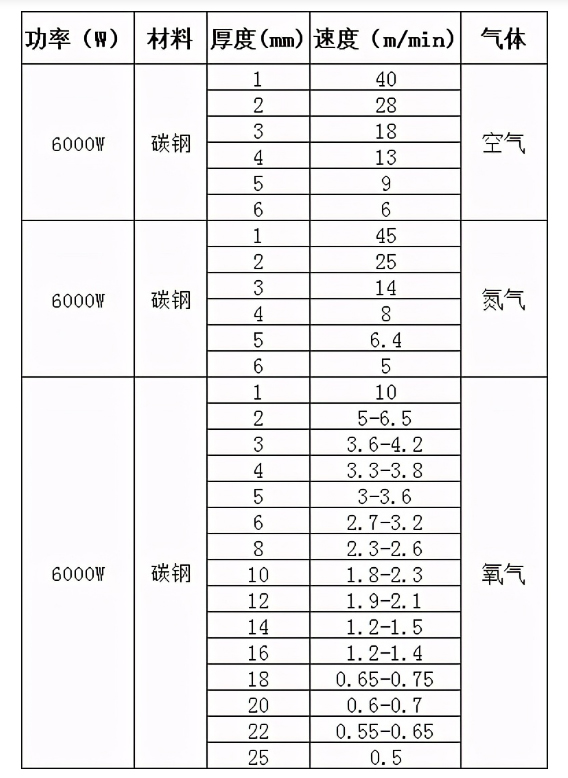

Le datha yokusika ingentla ibhekiselele kuphela, eyona nto iya kuba ngumphumo wokusika.

Isishwankathelo, xa usikwa iipleyiti zetsimbi zekhabhoni ngaphezulu kwe-6mm, kukusikwa kweoksijini kuphela kuxhaswa.Xa usika ngaphantsi kwe-6mm, ukuba kukho iimfuno ezicacileyo zokusika umgangatho kunye nokuchaneka, kuyacetyiswa ukuba kusetyenziswe ukusika i-nitrogen, esebenza kakuhle kwaye inokucutshungulwa ngokuthe ngqo kwisinyathelo esilandelayo, ngelixa ukusika i-oksijini kuhamba kancane kwaye akukhuthazwa.Xa usika ngaphantsi kwe-6mm, ukuba ukusika kuphela kuqwalaselwa okanye akukho mfuneko yenkqubo ecacileyo, ukusika umoya kunconywa, kunye neendleko ze-zero zegesi.

Ixesha lokuposa: Nov-23-2022